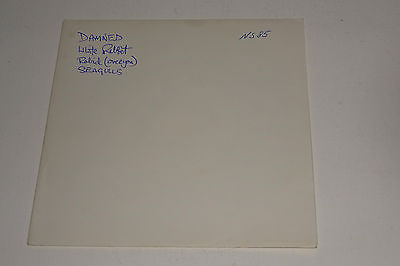

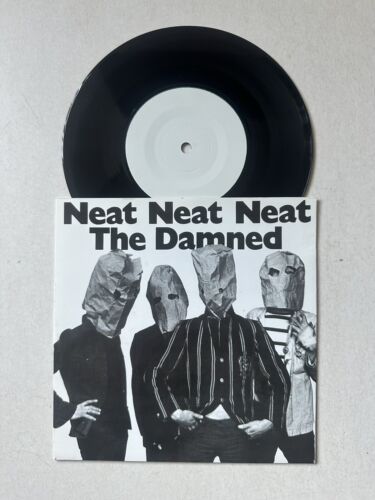

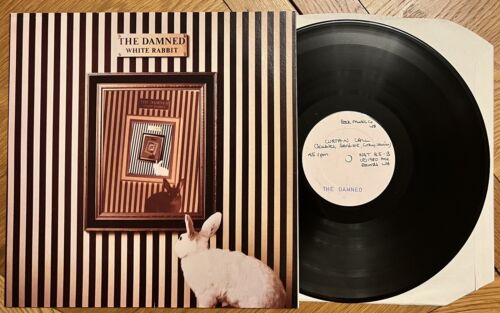

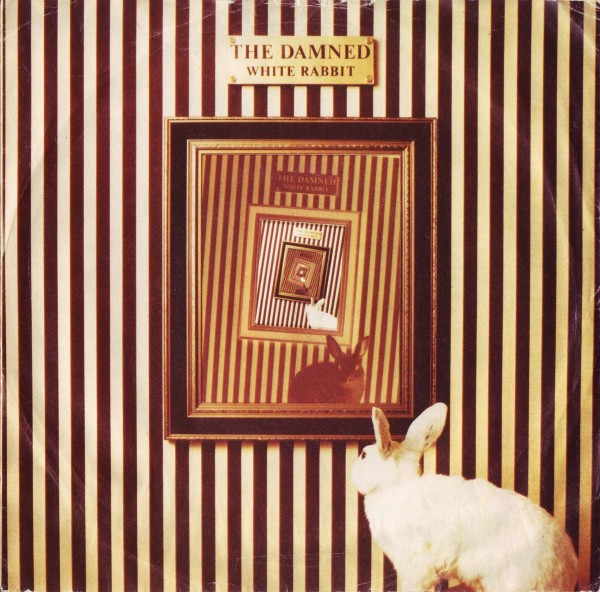

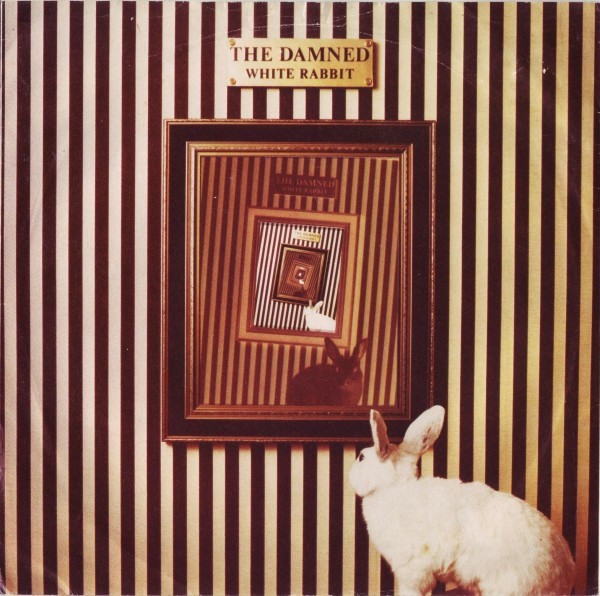

The Damned White Rabbit 1980 Big Beat Ns 85 German Test Pressing 7

This item have been sold for $ 1250.21

Item Description

echo2ndhand

The DamnedWhite Rabbit

- with paper labels, large centre

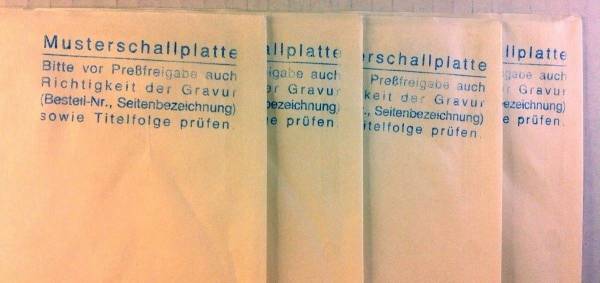

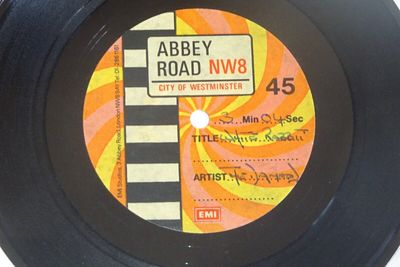

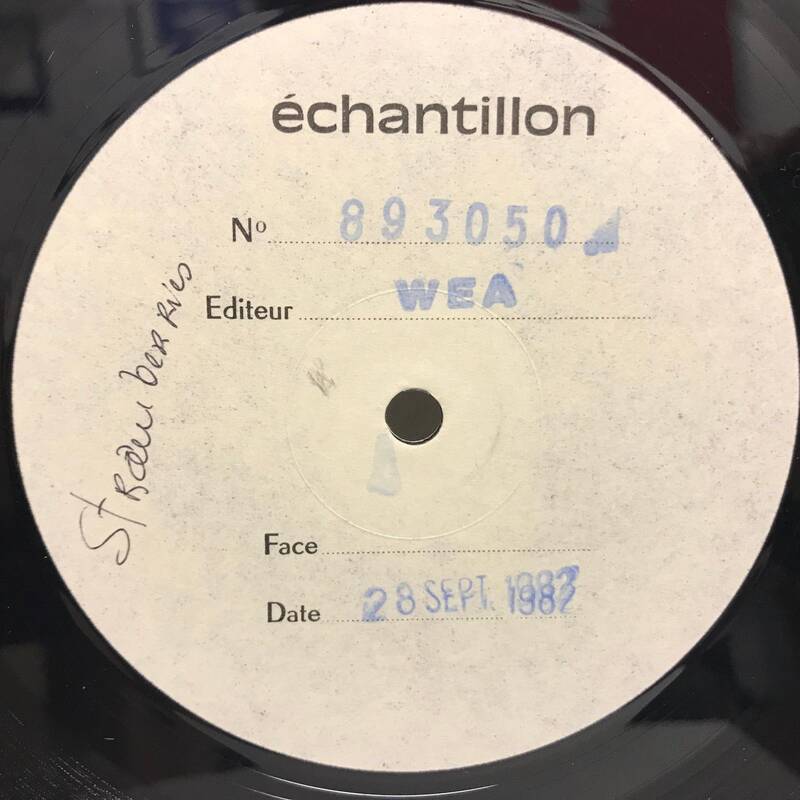

TEST PRESSINGS are manufactured to test the quality of the finished product before pressing thousands of records. Test pressings are made to ensure that the grooves themselves are clean, deep enough and formed correctly that the grooves, label and centre hole are not off-centre that the vinyl does not warp. Test pressings are supposed to be destroyed, but most of them end up being kept by the people to whom they are sent...

Only a few test pressings are made for each record usually 5 25 copies with plain white labels . These are sent out to the record company after first being checked by the quality control department at the pressing plant. The record company will then send copies to the Producer as well as the Artist and often a copy to the Cutting Engineer. Test Pressings are usually pressed on a special press that is very high quality and used only for test pressings. It is regularly serviced and only pure virgin vinyl is used for these discs. Consequently, white label test pressings are always highly sought after by collectors in the know because they will have the best sound quality that s possible to get.

Vinyl records are pressed using metal stampers and these stampers gradually deteriorate during the manufacturing process and so are usually replaced after every 500 to 1000 pressings. Test pressings have the highest sound quality as they are the very FIRST records to be pressed from a new set of stampers Virgin vinyl, is pure vinyl, not including any re-grounds or other extraneous material. Re-grounds are made from recycled vinyl, produced by grinding up faulty records and then melting these grounds down and combining them with virgin vinyl. For albums, usually only a low percentage of re-grounds are used, perhaps 20 or 25 , but often with 7 45-rpm records the percentage can go up to 50/50

SLEEVE: EXCELLENT

- no issues

:

Visually graded to Record Collector guidelines:

:

RETURNS?

:

QUESTIONS?

Please get in touch, will be glad to help